Nanotechnology expert and GrantTree Senior Technical Consultant Dr Barbara Souza asks whether MOFs hold the key to reducing carbon emissions and tackling climate change.

Metal-organic frameworks (MOFs) have been called a “miracle material” in the field of nanotechnology and carbon capture.

With climate change threatening businesses and communities around the planet, extracting greenhouse gasses from the atmosphere may be crucial to our attempts to limit further disruption.

Can MOFs help us do this?

MOFs and Carbon Capture

In August 2021, the Lawrence Berkeley National Laboratory serendipitously discovered that the switch-like mechanism of certain MOFs could be used to capture CO2. Building on years of MOFs-related research conducted by institutions across the world, the Laboratory described MOFs as “a sponge to soak up carbon dioxide”.

Senior scientist Jeffrey Long explained: “We showed that the capture and release of carbon dioxide from the MOF could be accomplished using much smaller temperature changes than required for other technologies, giving it a big advantage over conventional ways to capture CO2.”

This process does not require large quantities of high-temperature steam, which has been an obstacle to large-scale carbon capture in the past. What’s more, the captured CO2 can be extracted from the MOF and put to beneficial use in commercial products.

Professor Long added: “We also showed that variants of the MOFs could be efficient for the removal of CO2 from other gas mixtures, including biogas, natural gas, and even directly from air.”

What are MOFs?

Pioneered in the 1990s by UC Berkeley’s Professor Omar M Yaghi, MOFs are a nanomaterial formed when metal ions and organic ligands are combined to create a crystalline porous network.

During the production of MOFs, pores in their structure are filled with so-called ‘guest’ molecules or solvents. As these molecules are eliminated, they leave behind the empty pores, which can then be used to capture and store gases in the same way that the small holes in a sponge soak up water.

Indeed, Professor Yaghi’s recent research has focused on building literal MOF “water sponges” capable of extracting moisture from the atmosphere at very low concentrations, requiring minimal energy input during the water release step.

The first commercialised MOF product was launched in 2016 by a team from Queen’s University Belfast. They declared MOFs a “tailor-made solution for a global CO2 problem” since their super-absorbent nature allows them to be “highly tuned for CO2 capture”. This overcomes the low CO2 capacity and CO2/N2 selectivity of conventional sorbents used in carbon capture and storage (CCS).

How do MOFs compare to traditional adsorbents?

Your Monthly Innovation Update

What are the limitations of using MOFs?

Professor Yaghi’s decades-long research into MOFs has revealed multiple applications, from cleaning polluted air to harvesting drinkable water in the desert. Some of these applications have massive potential for commercialisation, yet MOF technology has still to reach mass-market implementation in many of these fields.

This is partly due to a lack of engineering studies of MOFs in real-world settings, compared with the ever-growing wealth of scientific evidence in favour of their use. In 2020, a team from Imperial College London, led by Prof. Camille Petit, wrote in the journal Molecular Systems Design & Engineering:

“No pilot-scale or larger-scale study exists on MOFs for carbon capture. Beyond material scalability issues, this clear gap between the scientific and engineering literature relates to the absence of suitable and accessible assessment of MOFs in an adsorption process.”

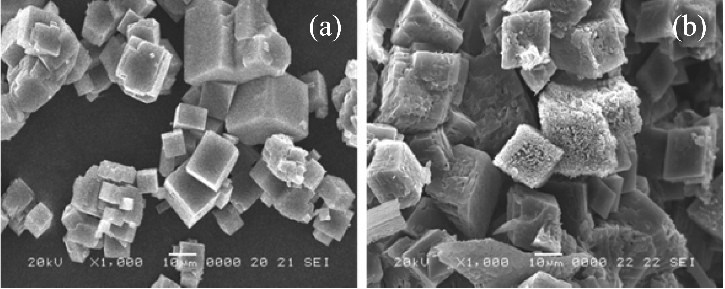

Physical synthesis of MOFs can be both expensive and time-consuming, a prohibitive factor for further research, according to a Scientific Reports article published in late 2021. Instead, software simulations powered by machine learning have enabled researchers to precisely model tens of thousands of MOFs, allowing “best candidate” MOFs to be identified.

Traditional MOF synthesis is also not especially environmentally friendly, requiring large quantities of heat and other forms of energy. This can reduce or even completely cancel out the environmental benefit of using MOFs for carbon capture. One possible solution to this problem is developing sustainable fabrication technologies, such as the mechanochemical production process pioneered by MOF technologies.

As scientists conduct more modelling and practical research, we should gain a better understanding of which MOFs are most suitable for CO2 adsorption and offer the lowest total cost of implementation for CCS. This would strengthen the economic and environmental cases for mass-market uptake.

The verdict

Numerous studies have highlighted the potential for MOFs to be used in removing CO2 from coal flue gas and other pollutant streams without requiring large quantities of energy to regenerate the adsorbent once it has reached capacity.

However, we are still in the foothills of MOFs-related research. Uncertainties remain about the economic viability of using MOFs at scale and for engineering research, as do questions about the environmental repercussions of MOF synthesis and the reality of using this relatively nascent technology to achieve a net reduction in the concentration of greenhouse gas emissions in our atmosphere.

What is certain is that MOFs are an extremely promising material with potentially far-reaching ramifications for our battle against the climate emergency. To unlock these possibilities, this exciting field urgently requires more attention, more research, and, ultimately, more investment.

GrantTree makes innovation easier by connecting your business with R&D Tax Credits, grants and other forms of funding. Get in touch to learn more about the funding options open to your company.